Exploring the Mechanics of Internal Combustion

Internal combustion engines (ICEs) have been fundamental to automotive and vehicle transport for over a century, powering a vast majority of cars, trucks, and motorcycles worldwide. These complex machines convert chemical energy stored in fuel into mechanical energy, driving the wheels of vehicles. Understanding their operational principles, from the basic four-stroke cycle to modern advancements, provides insight into the engineering marvels that underpin our global mobility.

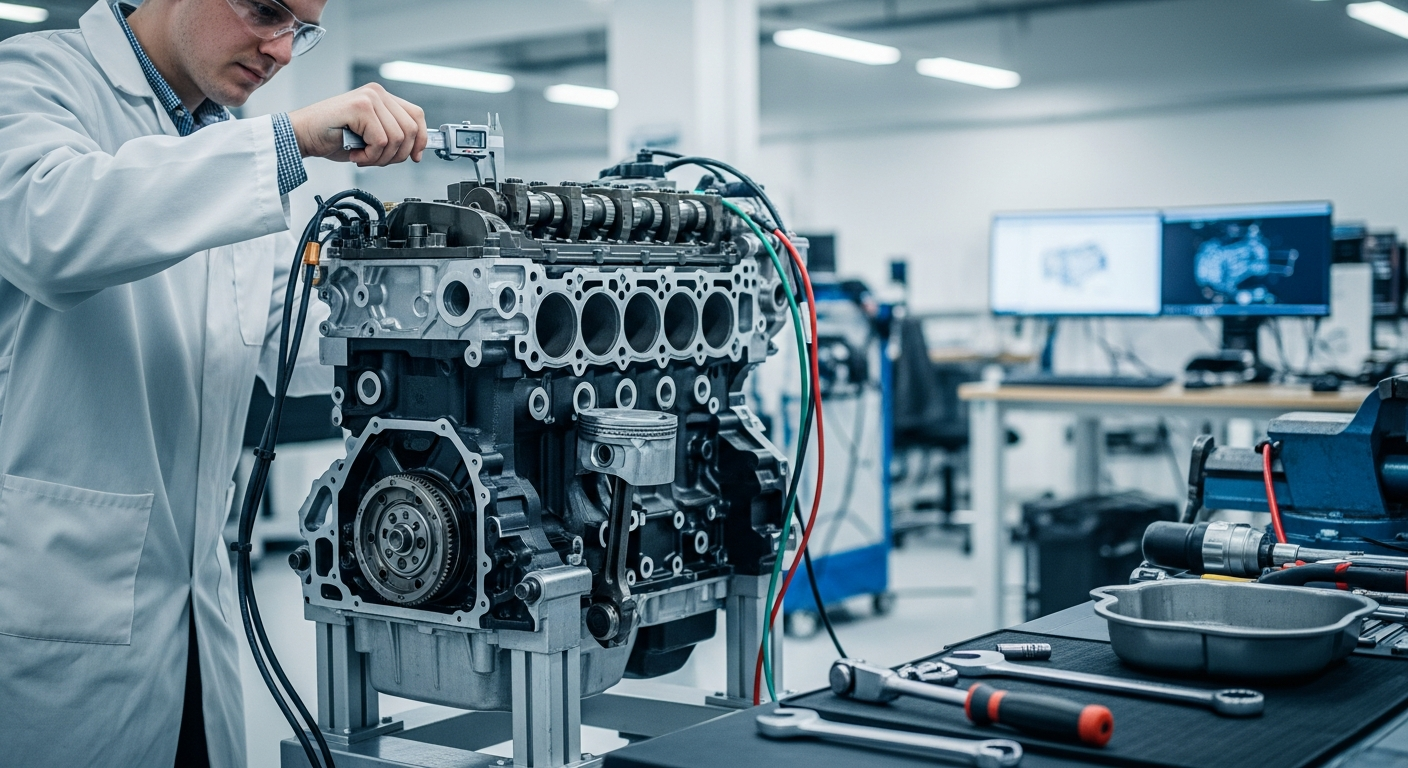

Understanding Internal Combustion Engine Engineering

Internal combustion engine engineering involves the design, development, and production of engines that generate power by burning fuel within a confined space. This field integrates principles from thermodynamics, fluid mechanics, materials science, and mechanical design. Engineers work to optimize various engine components, including cylinders, pistons, connecting rods, crankshafts, valves, and spark plugs, to ensure efficient and reliable operation. The primary goal is to maximize power output while minimizing fuel consumption and emissions, a continuous challenge that drives ongoing research and technological advancements in automotive design and manufacturing.

How Does the Internal Combustion Powertrain Function?

The powertrain in a vehicle refers to the entire system that generates power and delivers it to the driving wheels. At its core, the internal combustion engine initiates this process. Fuel, typically gasoline or diesel, is mixed with air and ignited within the engine’s combustion chambers. This controlled explosion creates high-pressure gases that push a piston, converting the chemical energy into linear mechanical motion. This linear motion is then transformed into rotational motion by the crankshaft. From the crankshaft, power is transmitted through the transmission, which adjusts gear ratios to match vehicle speed and load requirements, and then to the driveshaft, differentials, and finally to the wheels, propelling the vehicle forward. This intricate sequence ensures effective mobility and transport.

Enhancing Engine Efficiency and Design

Efficiency in internal combustion engines is a critical aspect, influencing fuel economy and environmental impact. Modern engine design focuses on various strategies to improve how effectively fuel energy is converted into useful work. Technologies such as direct fuel injection, variable valve timing, turbocharging, and cylinder deactivation are widely employed. These innovations allow engines to operate more effectively across different speeds and loads, reducing fuel waste. Aerodynamics also plays a significant role in overall vehicle efficiency, reducing drag and allowing the engine to work less to maintain speed. Continuous refinement in engine architecture and control systems remains a priority for automotive engineering.

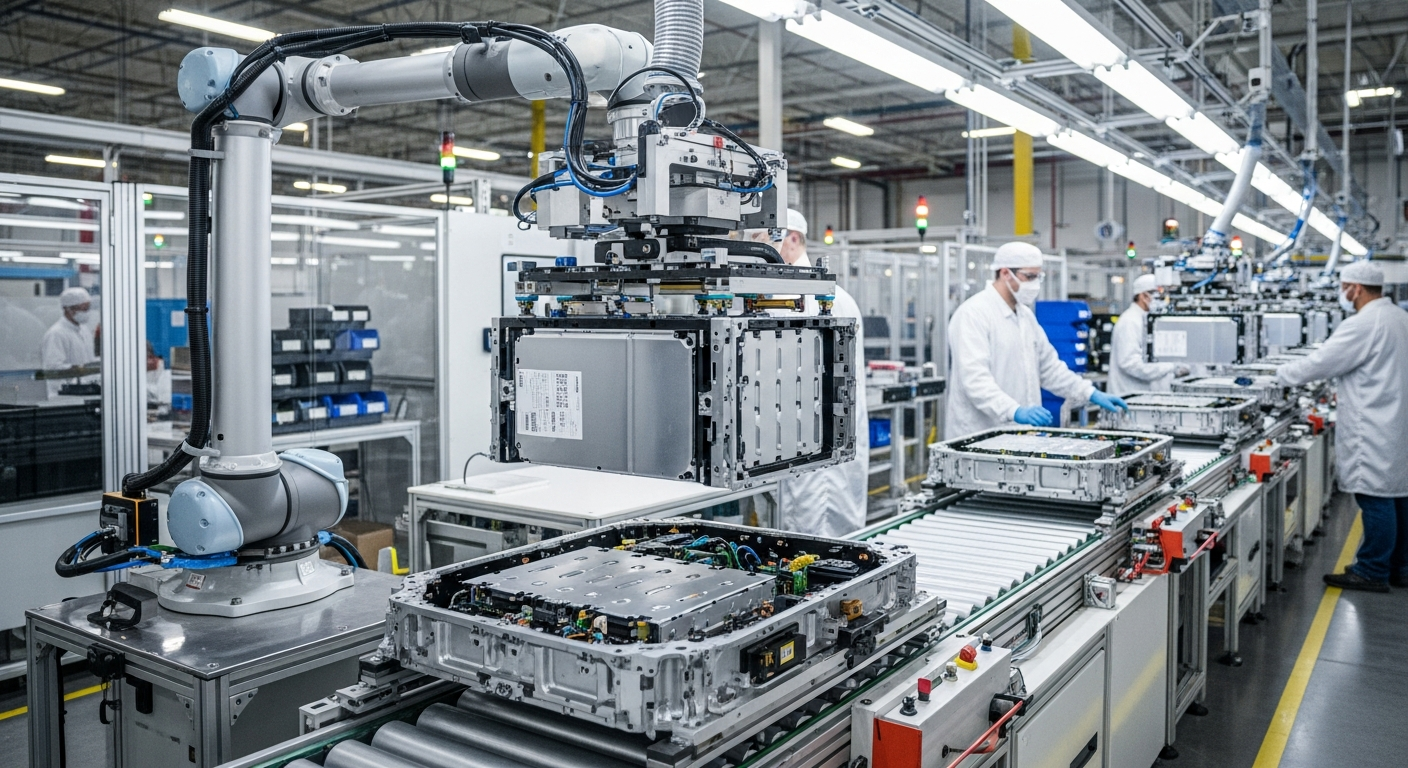

The Role of Materials and Manufacturing in Engine Development

The choice of materials and advanced manufacturing processes are pivotal in the evolution of internal combustion engines. Engine components must withstand extreme temperatures, pressures, and mechanical stresses. Lightweight yet robust materials like aluminum alloys, high-strength steels, and advanced composites are crucial for reducing engine weight and improving fuel efficiency without compromising durability. Precision manufacturing techniques, including advanced machining, casting, and additive manufacturing, ensure tight tolerances and optimal performance of engine parts. These developments contribute to the longevity and reliability of vehicles, impacting overall automotive quality and reducing the need for frequent maintenance.

Future Directions for Internal Combustion Technology

While electric and hybrid vehicles represent a significant shift in the automotive landscape, internal combustion technology continues to evolve. Research areas include advanced combustion strategies, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion, aimed at further reducing emissions and improving thermal efficiency. The integration of sophisticated electronic controls and connectivity features also enhances engine management, enabling more precise fuel delivery and ignition timing. Furthermore, the development of sustainable fuels, like synthetic fuels or biofuels, could extend the relevance of ICEs in a future focused on reduced carbon footprints. These innovations highlight the ongoing commitment to engineering advancements in the transport sector.

In conclusion, internal combustion engines, while a mature technology, continue to be a subject of intense engineering and technological innovation. From the fundamental principles of converting fuel into motion to the sophisticated designs and materials used in modern powertrains, these engines are central to global automotive and vehicle transport. Ongoing efforts to enhance efficiency, reduce environmental impact, and integrate new technologies demonstrate a dynamic future for internal combustion, even as the industry explores diverse mobility solutions.