Leveraging Biomimicry in Industrial Design

Biomimicry, the practice of emulating nature's time-tested patterns and strategies, is revolutionizing industrial design. This innovative approach draws inspiration from biological systems to create more efficient, sustainable, and resilient products and processes. By tapping into nature's 3.8 billion years of R&D, companies are finding ingenious solutions to complex industrial challenges.

The Origins and Evolution of Biomimicry in Industry

The term “biomimicry” was coined in the 1990s by biologist and author Janine Benyus, but the practice of learning from nature has roots that stretch back to ancient times. Leonardo da Vinci’s flying machine designs, inspired by bird wings, are early examples of biomimetic thinking. However, it wasn’t until the late 20th century that biomimicry began to be systematically applied in industrial contexts.

In the 1950s, the development of Velcro by Swiss engineer George de Mestral, inspired by the hooks of burdock burrs, marked a significant milestone in biomimetic product design. This invention demonstrated the potential of nature-inspired solutions and paved the way for further exploration in the field.

Biomimicry’s Impact on Modern Industrial Processes

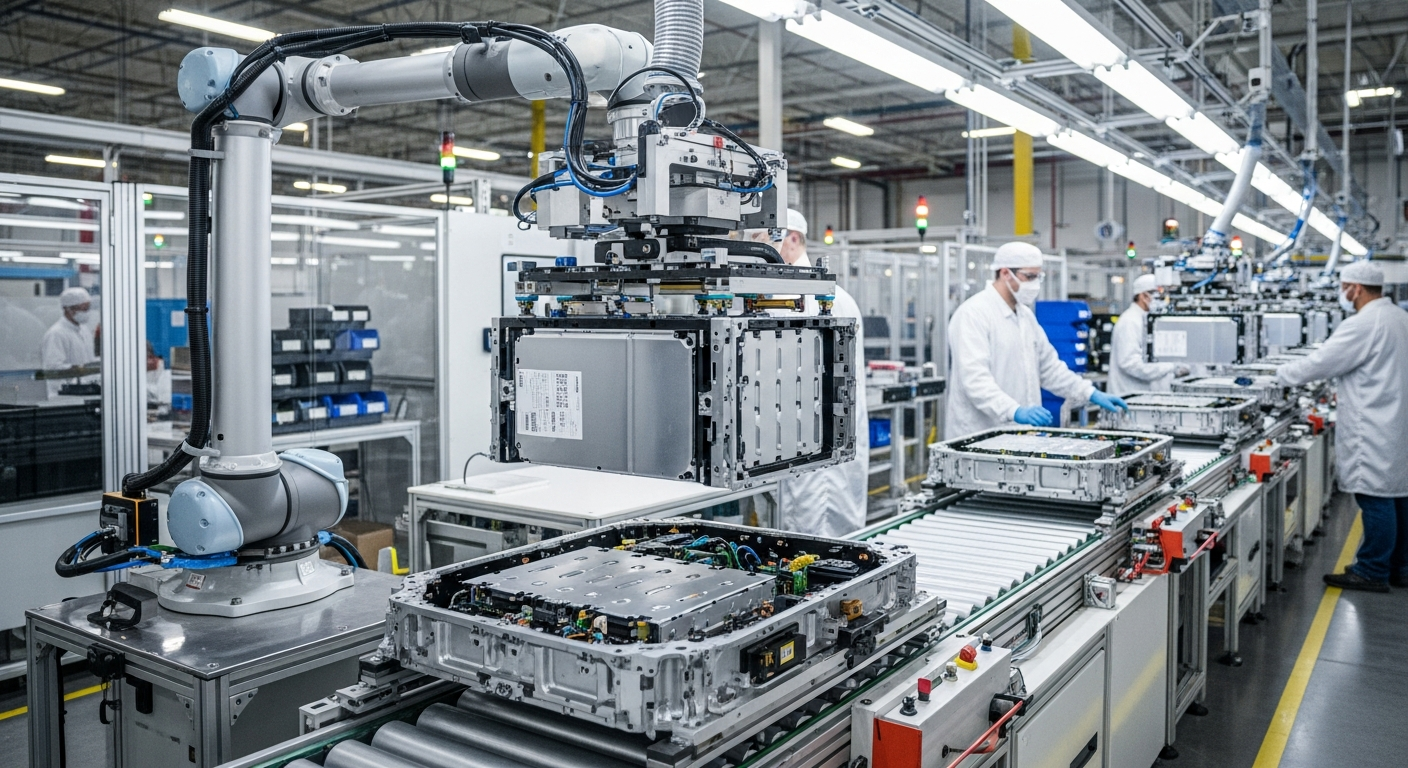

Today, biomimicry is transforming industrial processes across sectors. In manufacturing, companies are adopting nature-inspired approaches to optimize production lines and reduce waste. For instance, some factories now use algorithms based on ant colony behavior to streamline logistics and improve efficiency.

In the realm of materials science, researchers are developing self-healing materials inspired by human skin, potentially revolutionizing maintenance practices in industries ranging from aerospace to infrastructure. These materials can repair minor damage autonomously, reducing downtime and extending product lifespans.

Case Studies: Successful Applications of Biomimicry

Several companies have successfully implemented biomimicry principles in their industrial designs. One notable example is Sharklet Technologies, which developed a surface texture inspired by shark skin that naturally repels bacteria. This innovation has found applications in healthcare settings, reducing the need for harsh chemical cleaners.

Another case is the bullet train redesign in Japan. Engineers looked to the kingfisher’s beak to solve the problem of loud sonic booms created when the train emerged from tunnels. The resulting redesign not only eliminated the noise issue but also improved the train’s energy efficiency by 15%.

Challenges and Considerations in Implementing Biomimetic Design

While biomimicry offers immense potential, its implementation in industrial settings is not without challenges. One significant hurdle is the interdisciplinary nature of the field, which requires collaboration between biologists, engineers, and designers. This can sometimes lead to communication barriers and differing methodologies.

Additionally, translating biological principles into practical, scalable industrial solutions often requires significant research and development investment. Companies must carefully weigh the potential long-term benefits against short-term costs when considering biomimetic approaches.

The Future of Biomimicry in Industrial Innovation

As we look to the future, biomimicry is poised to play an increasingly crucial role in industrial innovation. Advancements in fields such as nanotechnology and 3D printing are opening up new possibilities for replicating nature’s intricate designs at scale.

Moreover, as sustainability becomes a central focus for businesses worldwide, biomimicry’s inherently eco-friendly approach aligns perfectly with the growing demand for green solutions. By emulating nature’s closed-loop systems, industries can move closer to achieving true circular economy models.

Key Insights for Implementing Biomimicry in Industry

• Start with function: Focus on the underlying principles of natural systems rather than just mimicking forms.

• Collaborate across disciplines: Build teams that include biologists, engineers, and designers to foster innovative solutions.

• Think in systems: Consider how your biomimetic solution fits into larger industrial ecosystems.

• Invest in research: Allocate resources for thorough exploration of biological models and their potential applications.

• Embrace iteration: Nature’s designs evolved over millions of years; be prepared to refine and adapt your biomimetic solutions.

In conclusion, biomimicry represents a powerful tool for industrial innovation, offering solutions that are not only effective but also inherently sustainable. As industries continue to grapple with complex challenges, looking to nature for inspiration may well be the key to unlocking the next wave of groundbreaking designs and processes. By embracing the principles of biomimicry, businesses can tap into a vast reservoir of tested strategies, paving the way for a more efficient, resilient, and harmonious industrial future.